0102030405

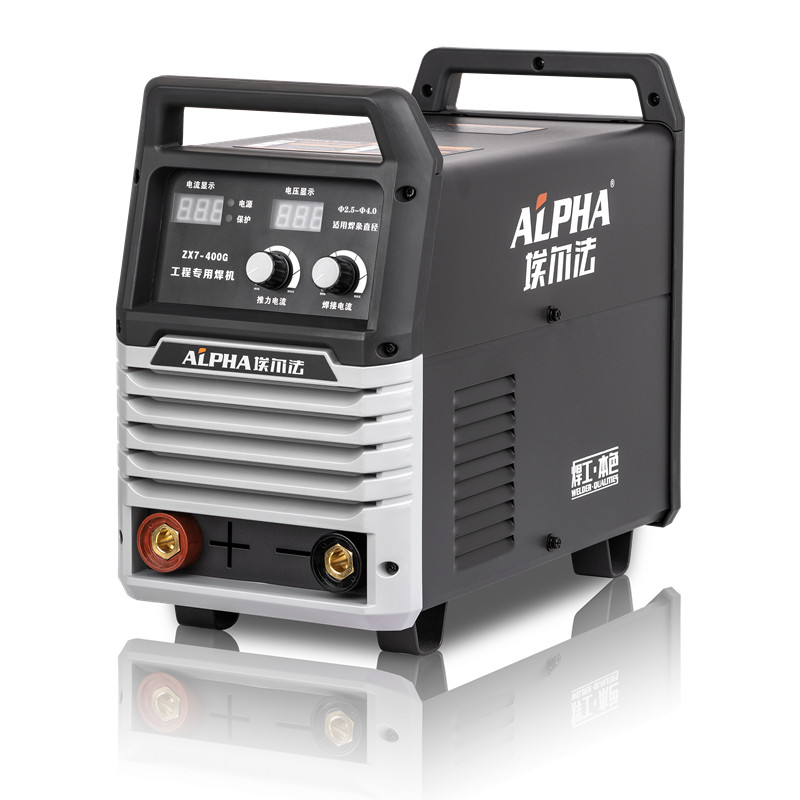

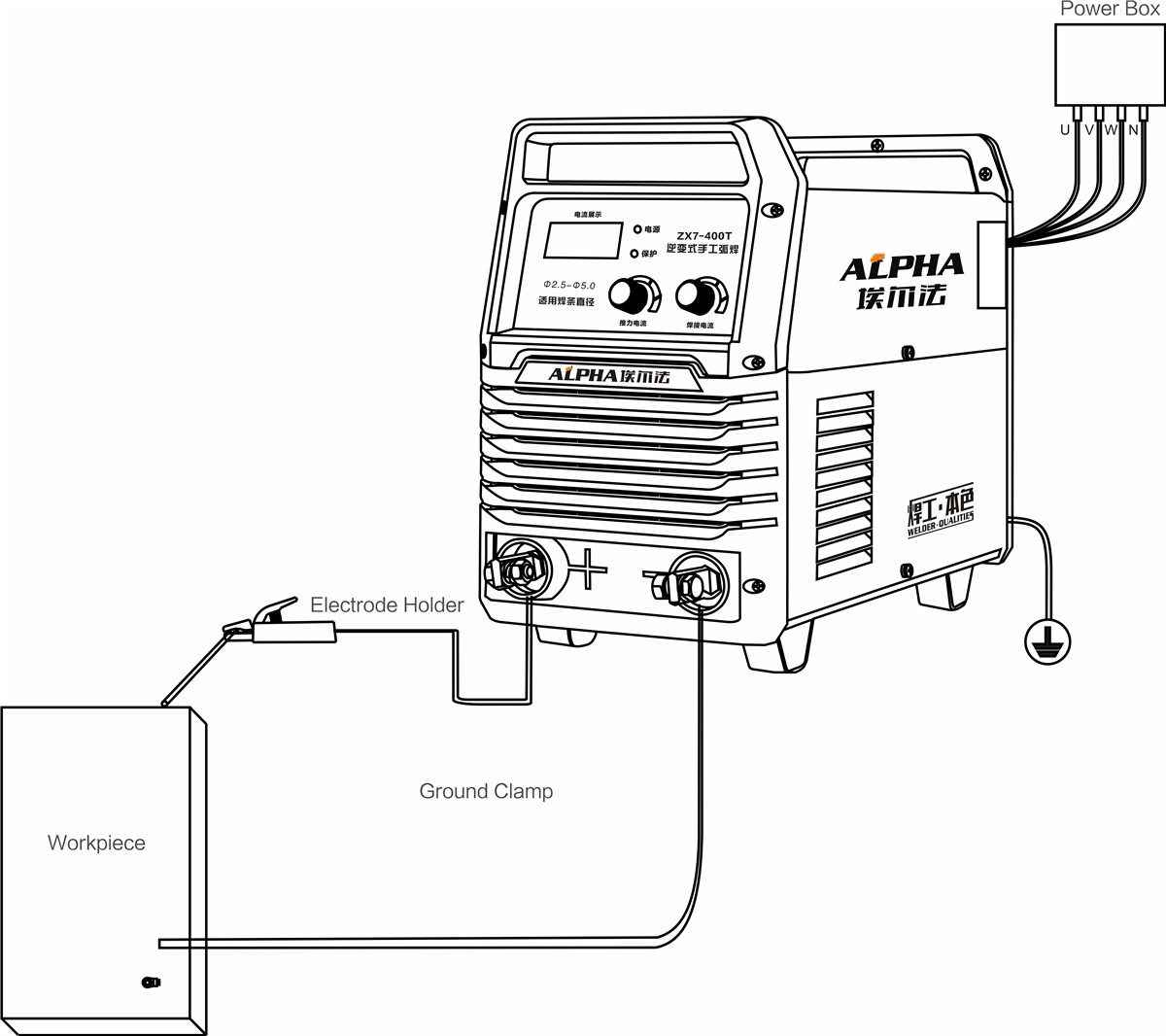

250A/300A Engineering High Duty Cycle Portable ARC/MMA Welder

01

2018-07-16

1x Electrode Holder

view detail

01

2018-07-16

1x Ground Clamp

view detail

01

2018-07-16

1x Welding Mask

view detail

01

2018-07-16

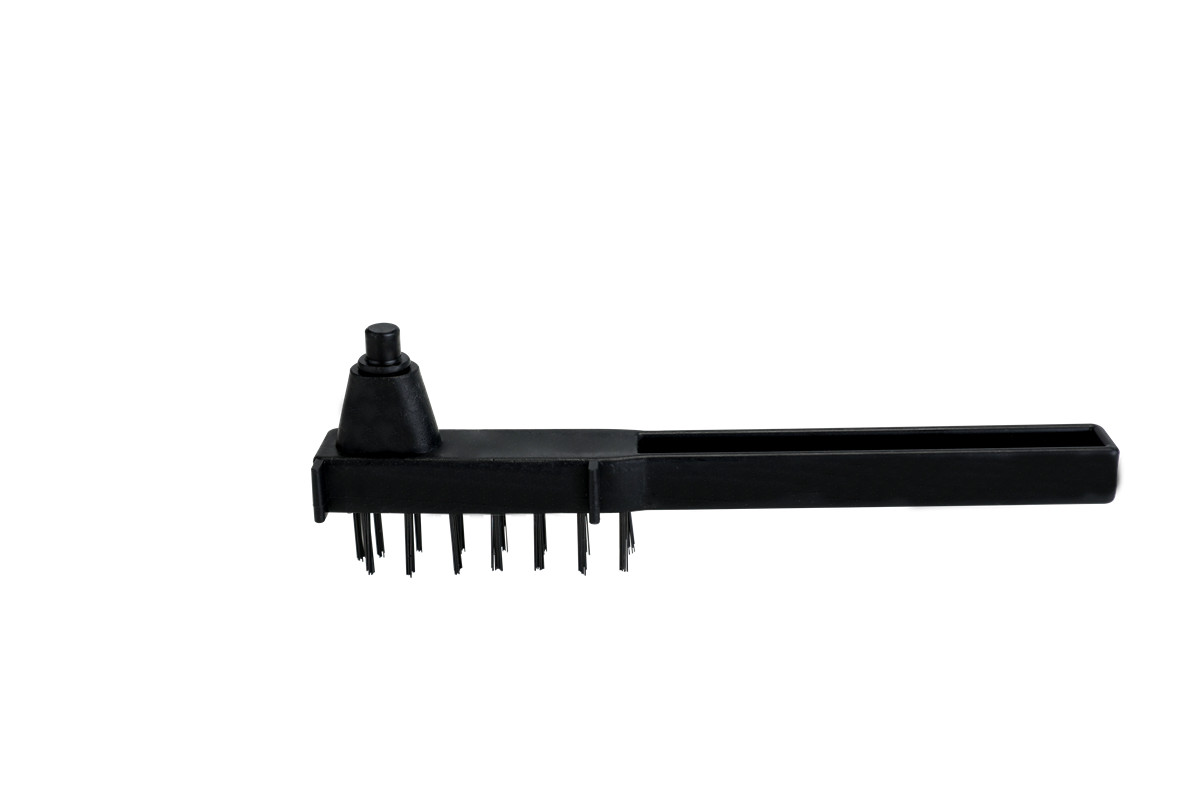

1x Brush/Hammer

view detail

01

2018-07-16

Welding Helmet

view detail

01

2018-07-16

Welding Gloves

view detail

01

2018-07-16

Electrodes E6013

view detail

01

2018-07-16

Lift TIG TORCH

view detail

Send Email

Send Email whatsapp

whatsapp