01

AVIATION

2024-05-27

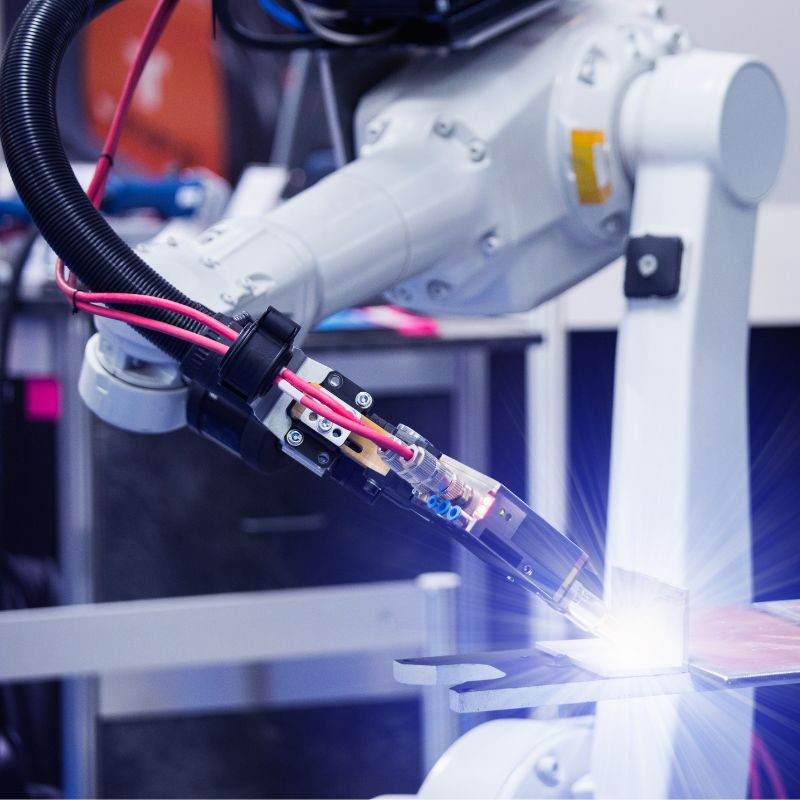

Welding, in particular, is crucial for joining metal parts, repairing damages, and enhancing the structural strength of aircraft components. Precision welding ensures the integrity of critical elements, such as engine mounts, fuselage frames, and landing gear, essential for safe flight operations

View

More

01

SHIPBUILDING

2024-05-27

Considering the cyclical and unpredictable nature of waves, the structural ship components must be produced with maximum quality. Ships are exposed to significant dynamic loading due to unpredictable buoyancy forces and wave configurations. Every ship must respond to these forces with transverse, longitudinal, torsional, and local strengths. But to do that, all structural components must have exceptional weld quality.

View

More

01

AUTOMOBILE

2024-05-27

Welding is commonly used to join together sheet metal parts in the automotive industry. These parts include brackets, hinges, spring seats, caps, covers, etc. Most of these parts are welded through TIG or MIG welding techniques.

View

More

01

MINING

2024-05-27

Mined products are today used in almost every consumer product, making mining a vital component of modern society. And since mining is critical to modern life, the manufacture of mining equipment is equally important.

It takes great precision and efficiency to achieve the structural integrity and massive scale required of the machinery used in mining. From towering cranes to intricate machinery, welding technologies lay the foundation for building strong and reliable mining structures, ensuring their durability and performance.

View

More

01

MUCLEAR

2024-05-27

During nuclear welding, the fusion application must perform perfectly without compromising weld quality. Since manual welding introduces the risk of human error, an automated process like orbital welding is recommended. Orbital welding provides high-specification welds that the nuclear industry demands by relying on a mechanized system to rotate an arc 360 degrees around a stationary workpiece. As such, orbital gas tungsten arc welding (GTAW) is suitable for the welding of tubes, pipes, vessels, and other components used in the nuclear power plant.

View

More

01

MEDICAL

2024-05-27

Welding plays a crucial role in the medical device industry, as it is the process that joins different metal components together to form the devices used in various healthcare settings. The stringent requirements of the medical industry demand that welding solutions provide high durability, reliability, and consistency to ensure devices can safely perform their intended functions.

View

More

Send Email

Send Email whatsapp

whatsapp