WELD CLASS-WHAT IS MMA WELDING

MMA Welding: A Comprehensive Guide

MMA welding, also known as manual metal arc welding or shielded metal arc welding, is a popular and versatile welding process used across various industries. This article aims to provide a comprehensive guide to MMA welding, including its definition, process, equipment, applications, advantages, and limitations.

What is MMA Welding?

MMA welding is a manual arc welding process that uses a consumable electrode coated in flux to lay the weld. The electrode is connected to a power source, and an electric arc is created between the electrode and the workpiece, generating the heat required to melt the base metal and the electrode. As the electrode melts, the flux coating also melts, creating a shielding gas and slag to protect the weld pool from atmospheric contamination.

The Process of MMA Welding

MMA welding involves several key steps:

-

Preparation: The workpiece must be cleaned and prepared before welding to ensure a clean and sound weld. This may involve removing any rust, paint, or contaminants from the surface.

-

Electrode selection: Choosing the right electrode is crucial for achieving the desired weld quality. Electrodes come in various types and sizes, each designed for specific applications and materials.

-

Setting up the equipment: The welding machine must be set up correctly, including adjusting the current, polarity, and other settings based on the type of electrode and the material being welded.

-

Striking the arc: Once the equipment is set up, the welder strikes the arc by bringing the electrode into contact with the workpiece and then quickly withdrawing it to create the arc.

-

Welding: The welder manipulates the electrode and controls the welding parameters to create the desired weld bead and ensure proper fusion with the base metal.

-

Slag removal: After each pass, the slag created by the flux coating must be removed to inspect the weld and prepare for the next pass.

Equipment for MMA Welding

MMA welding requires the following equipment:

-

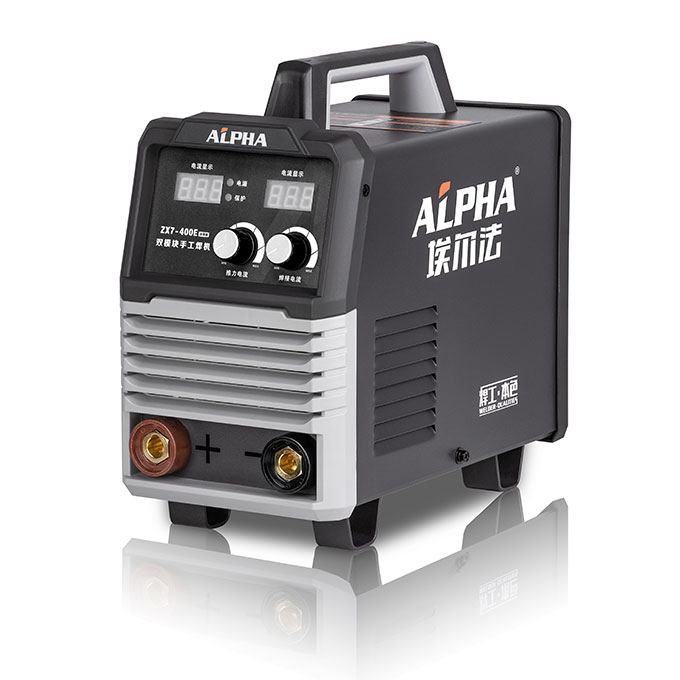

Welding machine: A power source capable of producing the necessary current and voltage for the welding process.

-

Electrodes: Consumable electrodes with a flux coating, available in various types such as rutile, basic, and cellulose, each suitable for different applications.

-

Personal protective equipment (PPE): Welders must wear appropriate PPE, including a welding helmet, gloves, protective clothing, and safety glasses, to protect themselves from sparks, UV radiation, and fumes.

-

Welding accessories: This includes welding cables, electrode holders, ground clamps, and other accessories necessary for the welding process.

Applications of MMA Welding

MMA welding is widely used in various industries and applications, including:

-

Construction:MMA WELDING is commonly used in construction for joining structural steel, fabricating metal components, and repairing metal structures on-site.

-

Automotive and transportation: It is used for repairing vehicle components, fabricating custom parts, and performing maintenance on various transportation equipment.

-

Shipbuilding: MMA welding is used in shipyards for constructing and repairing ships, offshore platforms, and marine structures.

-

Maintenance and Repair: It is widely used for maintenance and repair work in industries such as mining, agriculture, and manufacturing.

Advantages of MMA Welding

MMA welding offers several advantages, including:

-

Portability: The equipment for MMA welding is relatively compact and portable, making it suitable for on-site and remote welding applications.

-

Versatility: MMA welding can be used to weld a wide range of materials, including carbon steel, stainless steel, cast iron, and non-ferrous metals.

-

Cost-effective: The initial investment for MMA welding equipment is relatively low compared to other welding processes, making it accessible to small businesses and hobbyists.

-

Simple setup: The equipment for MMA welding is straightforward to set up and operate, requiring minimal training and expertise.

Limitations of MMA Welding

Despite its versatility, MMA welding also has some limitations, including:

-

Productivity: MMA welding is generally slower compared to other welding processes such as MIG or TIG welding, making it less suitable for high-volume production.

-

Weld quality: Achieving consistent weld quality with MMA welding requires skill and experience, as the process is more sensitive to variations in technique and parameters.

-

Slag removal: The need to remove slag after each pass can increase the overall welding time and labor.

-

Operator fatigue: The manual nature of MMA welding can lead to operator fatigue, particularly during prolonged welding tasks.

In conclusion, MMA welding is a widely used and versatile welding process with applications across various industries. Its portability, versatility, and cost-effectiveness make it a popular choice for on-site welding, maintenance, and repair work. While it has some limitations, proper training and experience can help welders overcome these challenges and achieve high-quality welds using the MMA welding process.

Send Email

Send Email whatsapp

whatsapp